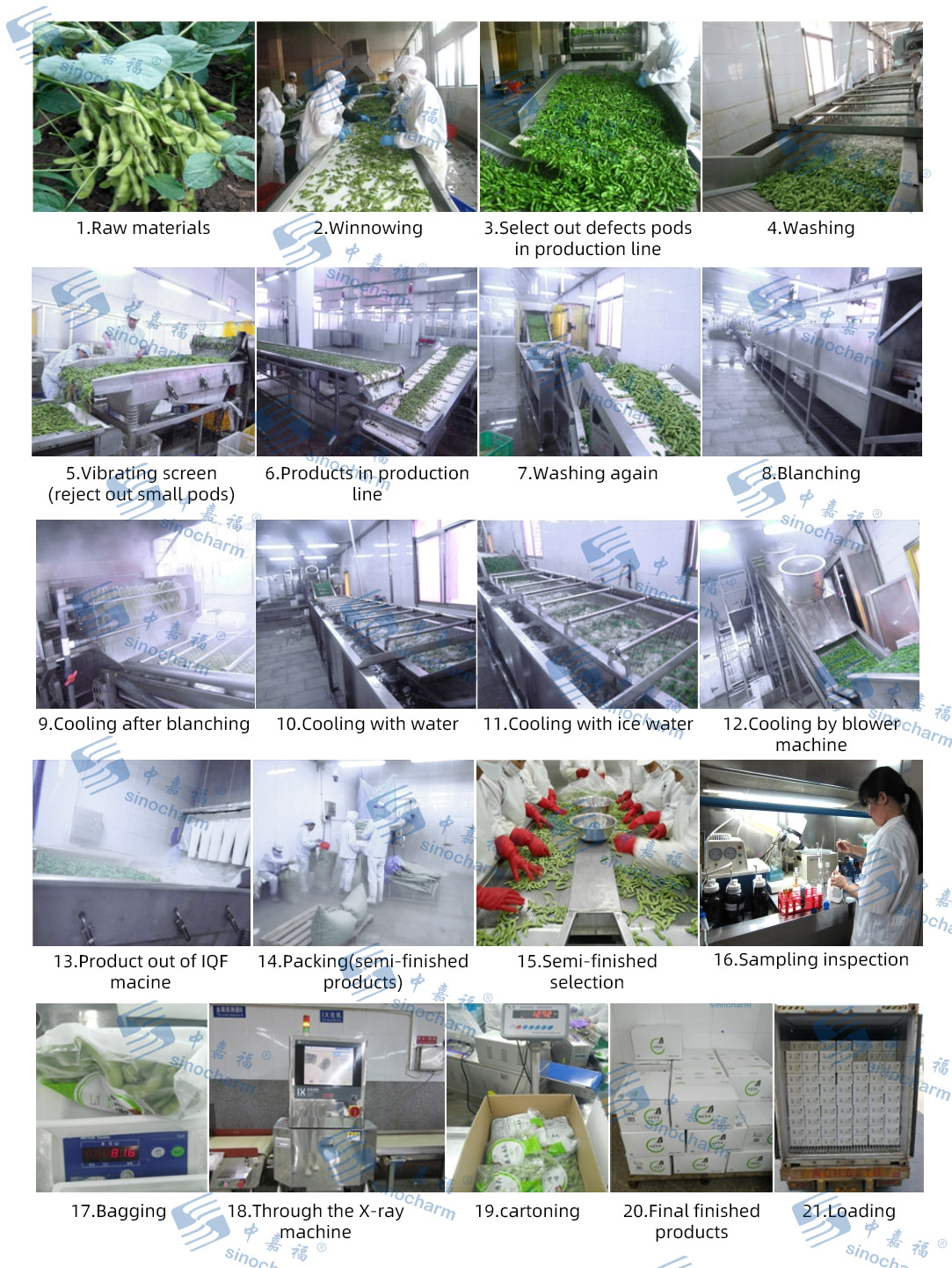

Flowchart of Frozen Edamame

Edamame processing flow control point:

(1) Raw materials: raw materials are checked and inspected based on CCP1,pesticide residue testing before taken before harvest, onlyqualified materials will be used and put onto production line.

(2) Selection: winnowing selection and manual selection to remove branches and leaves, insect damaged pods, small pods and foreign materials, etc.

(3) Cleaning: wash with running waterto remove stains, sand, dirt and other thingson the surface of the edamame pods.

(4)Blanching: itis strictly based on CCP2, and control the microto an acceptable level.

(5) Cooling and draining :cooled by ice water with temperature below 10 ℃, drained by shaker.

(6) Freeze: IQF frozen at a temperature -30 ℃ or below, weighted then store in cold warehouse with temperature -18 ℃~ -20 ℃ in time. (Could ice glazing by spray if customer requires).

(7)Secondary selection: pick out pods with spots, insect damaged pods, broken pods, flat pods, etc.

(8) Packaging: based on CCP3, all products been through X-ray machine and metal detection with Fe: 1.5mm, Sus: 2.5mm (or per customers’ requirements). Weighted and put into cold warehouse timely.